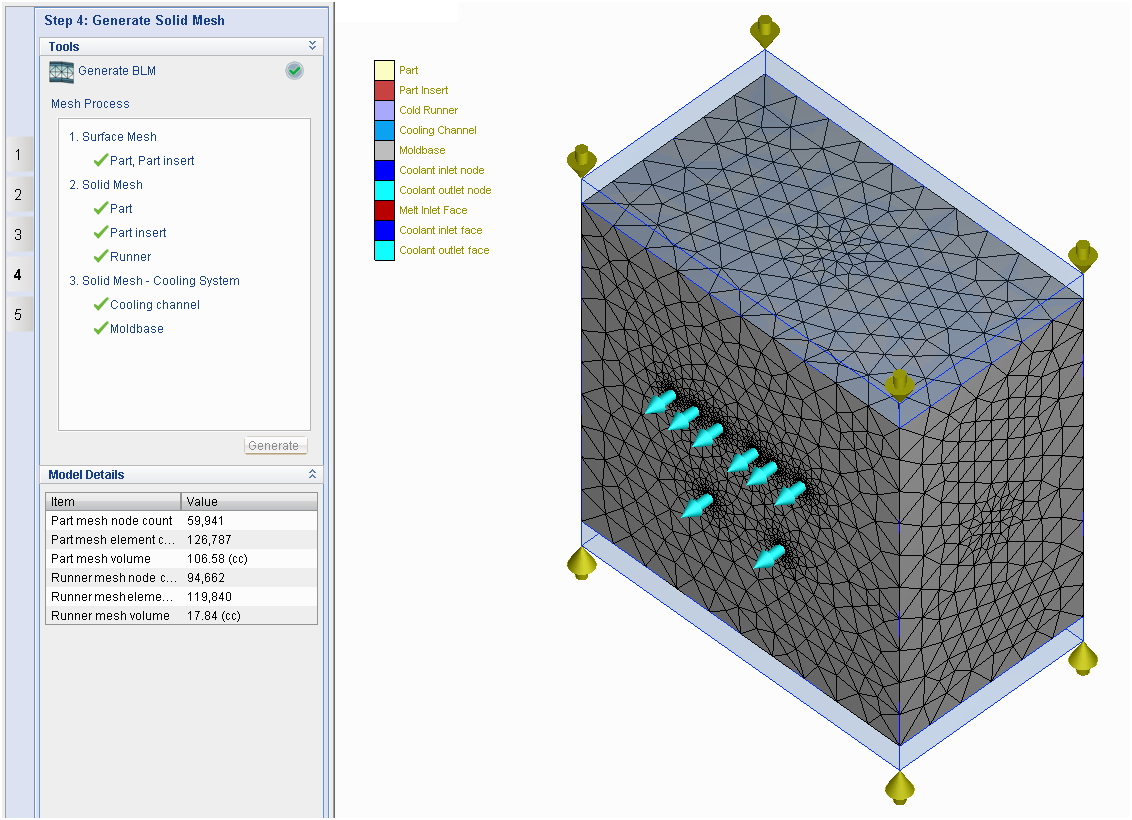

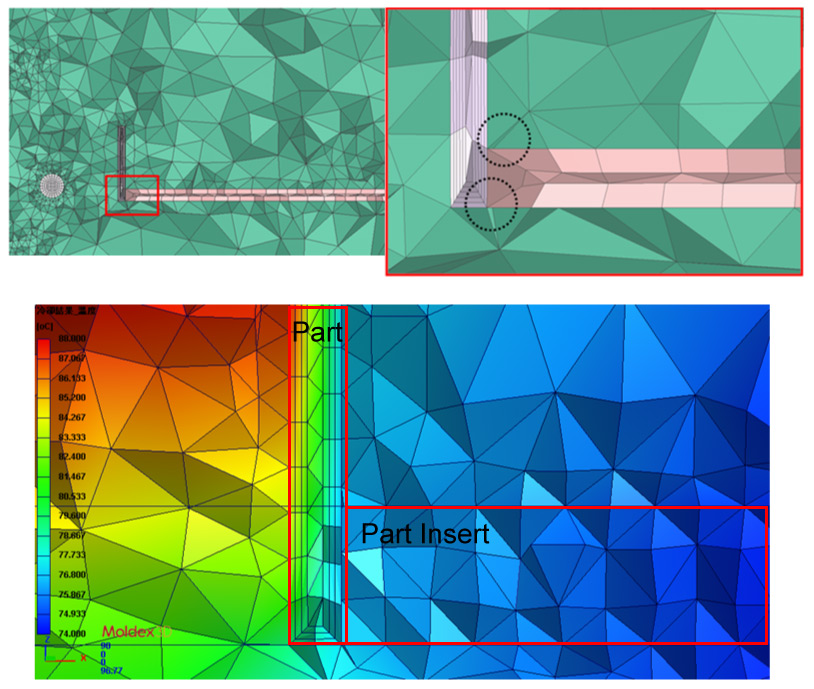

Insert molding is a high-performance and widely used molding technology. For insert molding simulation, Moldex3D pre-processing provides powerful functions to automatically generate a good quality mesh for users. Advanced users need very detailed analysis results, so a comprehensive mesh is necessary. However, it costs experienced users significant time and efforts in mesh building in order to create matching solid mesh among every component. To overcome this challenge, Moldex3D non-matching mesh technology now supports complete mold analysis that covers non-matching mesh generation between plastic parts, inserts and cooling systems, including mold base and cooling channels. Users will save lots of time doing meshing and still get reliable results. The following steps will show how to generate a cooling system non-matching mesh and its performance in analysis. Step 1. Open DesignerBLM/ Studio, and have Allow Non-matching faces checked. Step 2. Follow the regular pre-processing procedures: Import the model, build the runner system, and specify the cooling system. Note: It is necessary to set up the mold base first in order to generate non-matching cooling system mesh. Step 3. In Generate BLM Wizard, click Generate to start mesh generation, and all job items will be checked when completed. Note: Auto-grid will be marked behind the mold base job item once non-matching mesh generation fails, and the cooling system will be exported as Auto-grid (fast cool) instead. Step 4. As shown below, not all of the nodes connect with each other’s on the interface among part (purple), part insert (red) and mold base (green). The model then can be applied for molding simulation, and the results fully demonstrates continuous temperature distribution around the interface among different components. Transmission Pulley,Gearbox Pulley,Transmission Pulley Kit,Steel Transmission Pulley HONG KONG CRS INTERNATIONAL TRADING COMPANY LIMITED , https://www.crstrans.com

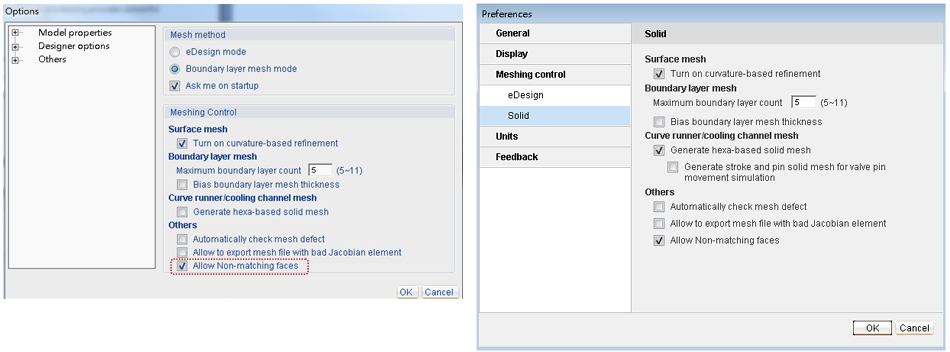

Enable the option to allow non-matching faces in Designer and Studio interfaces

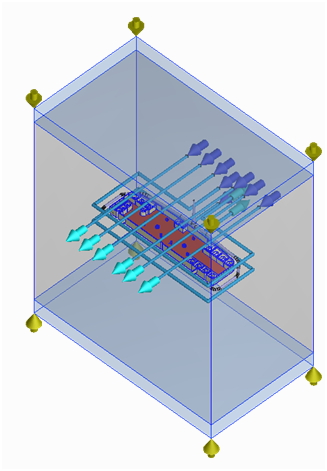

Multiple Component Molding (MCM) Model with a cooling system

Meshing and simulation result with non-matching mesh model

Speed Up Cooling System Modeling with Non-matching Mesh