Grand Dynasty Industrial Co., Ltd (GDI) was established on March 1984 by Mr. Chung-Yi Lin (Dr. Lawrence Lin’s father). Like so many other small companies in Taiwan at that time, it started as a family injection molding business serving the domestic market. Dr. Lawrence Lin (President), graduated in 1989 with a Ph.D. in Polymer Science and Plastic Engineering from the Department of Chemistry at the University of Massachusetts in Lowell, Massachusetts. After working at a research center of a Fortune 500 company in the Boston area for serval years, he joined GDI in November of 1993. (Source) Most of the cooling channels are made of conventional molds that adopt the drilling approach and use the baffle / bubbler or spiral type in the deeper portion; however, it is difficult to place due to the complex structure of the product. If the heat accumulation area is larger, the cooling time needs to be extended and the excessive temperature difference between the core and cavity can easily cause the product warpage. The Grand Dynasty team successfully solve the warpage issue in the power inspection socket product by using Moldex3D to simulate the creation of a conformal cooling channel mold before manufacturing. This led to a reduction in molding cycle time and the discovery of excellent design conformal cooling channel mold before manufacturing. In this study case, the warpage was improved by 49%, and the production efficiency was enhanced by 25%. Through the Moldex3D cooling analysis, we identified the issue of uneven temperature distribution between the core and cavity molds. The temperature difference of 47°C between the core and cavity molds of Part B caused the partial area of Part B to be concave, which resulted in the interference and looseness issue when assembling with parts A and C. Based on the conformal cooling channel technology. Modify the channel configuration to reduce the temperature difference between the core and cavity molds while also improving the warpage. The resulting optimized design was sent to 3D metal printing for mold production. As a result, the warpage was reduced by 49% and the molding cycle was decreased by 25%. There are increasingly more plastic parts used in the automotive industry, and the power inspection base is the main subject of this case. The power inspection base is composed of 3 plastic parts, as shown in Figure 1. Parts B and C are difficult to assemble due to interference, and it is easy for part B to loosen when combined with part A, as shown in Figure 2. The above-mentioned problems will result in poor quality and hinder smooth mass production. In order to improve these issues, Grand Dynasty Industrial utilized Moldex3D to analyze the root causes and determine the optimal cooling channel design. Figure 3 displays the component model geometry and cooling channel designs, both the original and optimized versions. Upon comparing the cooling results of the traditional and the conformal cooling channel (as shown in Table 1), it was found that the conformal cooling channel design yields better cooling efficiency and shorter ejection time compared to the original design. Further observation of the warpage deformation results (Table 2) also shows that the conformal cooling channel design can greatly optimize the warpage. high temperature but non-uniform lower temperature and uniform conformal cooling channel is better conformal cooling channel is better conformal cooling channel is better high temperature but non-uniform lower temperature and uniform conformal cooling channel is better conformal cooling channel is better After completing the 3D metal printing mold core, practical injection molding verification was carried out. It was confirmed that the conformal cooling channel design effectively reduces mold temperature through infrared thermal imaging. Additionally, the warpage deformation was obtained by using the 2.5D projection measurement method. The measurement results showed that the relevant dimensions have been improved, with an improvement range of 25% to 50% (Table 3). This improvement makes the subsequent assembly of parts B and C without interference and also makes the assembly of parts B and A not easy to loosen (Figure 4, 5), and the cooling time of actual production is also improved by 14% From the above results, it clear that the conformal cooling channel can effectively shorten the molding cycle and improve the warpage deformation problem. Grand Dynasty Industry successfully resolved the issue of uneven mold temperature distribution, especially the inconsistent temperature distribution between the core and cavity, through Moldex3D cooling analysis. In the process of designing cooling channel configurations, multiple cooling analysis scenarios were used to find the design with the smallest temperature difference between the core and cavity. This correct design solution was provided to 3D metal printing for mold manufacturing, greatly improving the warpage deformation problem. Window And Door Aluminum Profiles Aluminium Window Profiles,Aluminum Alloy Door,Aluminium Door Profiles,aluminium profiles for windows and doors,Aluminum Alloy Window GUANGDONG YONGLONG ALUMINUM CO.,LTD , https://www.yonglongaluminium.com

Summary

Challenges

Solutions

Benefits

Case Study

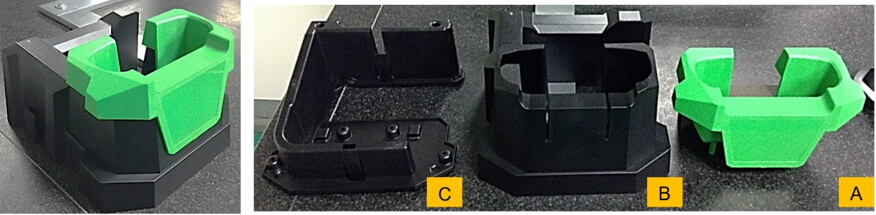

Fig. 1 The power inspection base and 3 plastic parts

Fig. 2 Poor quality due to component assembly problems

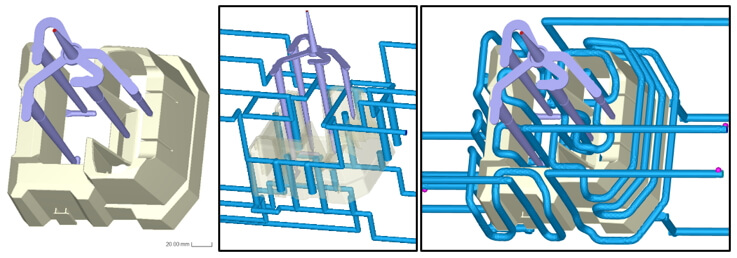

Fig 3 (a) Component model geometry and cooling channel design: (b) Original (c) Optimized.

Factor

Traditional cooling channel

Conformal cooling channel

Consequence

Finished product temperature

Time required to cool and eject

longer, 48s

shorter, 16s

Cooling efficiency

18%

35%

Average temperature

Mold temperature

high temperature

lower temperature

Table 1 Cooling results of traditional and conformal cooling channels

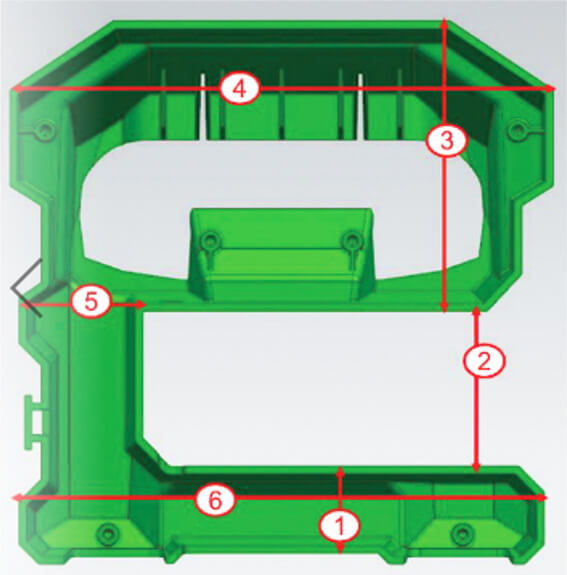

Number

Cad diagram

Deformation dimensions of traditional cooling channel

Deformation dimensions of conformal cooling channel

Improved efficiency

1

28.33

22.83(-5.5)

24.82(-3.5)

36%

2

55.14

49.28(-5.85)

51.60(-3.48)

40%

3

94.08

91.81(-2.27)

93.02(-1.05)

53%

4

176.13

173.93(-2.20)

174.60(-1.53)

30%

5

40.21

37.55(-2.66)

39.06(-1.15)

56%

6

170.3

166.58(-3.72)

168.22(-2.08)

44%

Table 2 CAE warpage results and improving efficiency

Number

Original 3D drawing dimensions

Deformation dimensions of traditional cooling channel

Deformation dimensions of conformal cooling channel

Improvement percentage

1

28.19

25.21(-2.98)

26.17(-2.02)

32.20%

2

54.87

46.05(-3.73)

47.88(-1.90)

49.10%

3

93.62

93.50(-0.12)

93.56(-0.06)

50.00%

4

175.26

175.66(+0.4)

175.56(+0.30)

25.00%

5

40.01

39.59(-0.42)

39.70(-0.31)

26.20%

6

169.45

169.78(+0.33)

169.66(+0.21)

36.40%

Table 3 On-site warpage results and improvement percentage.

Fig 4 Part B has good flatness and will not interfere with part C.

Fig 5. The assembly of parts B and A will not loosen and can be tightly connected.

Results

The Wider and More Popular Application of 3D Direct Metal Laser Sintering in the Mold Industry

Customer Profile