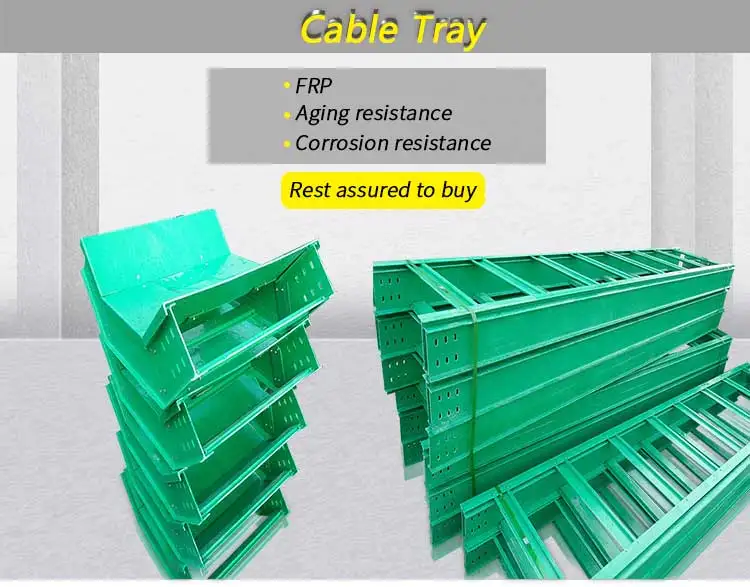

Fiberglass Reinforced Plastic FRP Cable Tray

Cable Tray Features:

1. Low cost, significant cost savings compared to standard traditional tray products.

2. Light in weight, wide range of sizes.

3. Fast heat dispersion.

4. Strong enough to withstand short circuits. Provides strength, rigidity without additional hardware.

5. Adapts to difficult architectural designs to accommodate changes in direction and elevation of cable runs.

6.Flexible, easy and fast installation. Design allows cable exit or entry at any point.

7. Cables can be secured to clamps or ties.

8.Various hardware accessories available to fix, support and install.

9. Safe smooth edge design to protect cable.

10.Easy for line check and cleaning , easy maintained.

Cable Tray Structure Types:

1. Groove series.

2. Stepped series.

3. Tray series.

FRP Cable Tray Specifications:

1. Width:100mm,150mm,200mm,300mm,400mm,500mm,600mm,800mm,etc.

2. Height: 50mm,100mm,150mm,200mm,etc.

3. Length: 1000mm,1500mm,2000mm,2500mm,3000mm,etc.

4. Material: FRP, SS304, Hot dipped galvanized steel,etc.

FRP Cable Tray Applications:

DHQ series of FRP bridge used in voltage under 10 kv power cable, as well as the control cable, lighting, pneumatic,

hydraulic pipe line and other indoor and outdoor overhead in cable trench, the laying of the tunnel.

Fiberglass Cable Tray Structure Characteristics DHQ series of FRP bridge has a wide application, high strength,

light weight, reasonable structure, low cost, long service life, strong corrosion, simple construction, flexible wiring,

installation standards, the characteristics of beautiful appearance.

Fiberglass Cable Tray Fiberglass Cable Tray,Cable Tray,Light Duty Cable Tray,Ladder Cable Tray Hebei Long Zhuo Trade Co., Ltd. , https://www.hblongzhuo.com

Cone concentrator

It is modified by a fan-shaped chute, which removes the side wall of the circular sector-shaped chute to form an inverted cone, which is the working surface. The side effect of the fan-shaped chute and the obstruction of the slurry flow are eliminated, thereby improving the sorting effect and improving the processing capacity of the device.

The Cone Concentrator was first developed in Australia in the late 1950s and used to treat low grade beach sands. China was successfully developed by Guangzhou Nonferrous Metals Institute in the late 1970s, and was produced by the Ningde Gravity Selection Plant and the Ningde Plant of the city. The conical concentrator produced has a diameter of 2000mm and is composed of a single-layer cone and a double-layer cone. Each cone has 6 fan-shaped chutes, generally consisting of 5 cones or 7 cones. A cone concentrator consists of only 4.5m2. . The excavation device can be installed in the concentrator vessel or, for processing by the beach placer ore developed to ordinary processing, such as baddeleyite, titanium, iron ore, iron, tantalum and niobium ore, tin ore.

The factory uses FRP as the material to manufacture the conical concentrator and lining with polyurethane wear-resistant rubber. The structure and shape of the representative three-segment seven-cone cone concentrator are shown in the following figure. The main technical parameters are listed in the following table.

Figure

Main technical parameters of cone concentrator (Ningde Gravity Concentrator)

Cone diameter / mm

Cone angle / (°)

Fan chute size / mm × mm × mm

Slot width / mm

Suitable person size / mm

Processing capacity / (t / h)

Feed concentration (%)

Single cone

Double cone

2000

145

147

1100×290×150

4~8

0.04~1.0

45~65

60~65